|

|

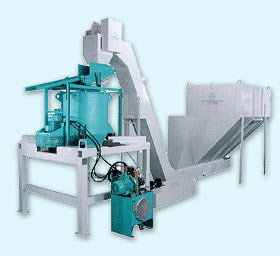

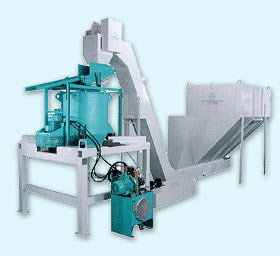

Swarf preparation Swarf preparation

Hydramax 4 / 5 ·

Scoro Z3 / Z4

The advantages are obvious:

higher sale

proceeds for dried swarf,

nearly 100% recovery of cooling lubricant,

compact design, fully automatic operation

|

|

Problem:

Big losses arise through the disposal of

oily swarf. This is why the recovery of the oil is an important economic

factor. In addition, the dried swarf can be further processed as a valuable raw

material.

We have the solution:

Manual or fully automatic

swarf processing. Because of their design, continuous centrifuges can be placed

directly underneath the discharge conveyors of the processing machines. This

saves space and money. |

| |

|

|

All fully automatic

continuous and push centrifuges can be expanded to complete fully automatic

swarf processing units in combination with conveyors, lift-tip devices and chip

breakers.

Furthermore we offer individual solutions for swarf handling

(chip extraction, chip transport, ...) on

inquiry.

|

|

|

Technical data:

| |

Continuous

centrifuges |

Push

centrifuges |

Conveyor |

Chip

breaker * |

| |

Scoro Z3 |

Scoro Z4 |

Hydramax 4 |

Hydramax 5 |

KF 380 |

V 400 |

V 500 |

|

| Drive power kW |

2,2 |

3 |

3 |

4 |

0,37 |

4 |

5,5 |

|

| Drum diameter mm |

300 |

400 |

400 |

500 |

- |

- |

- |

|

| Throughput ** kg/h |

180 |

350 |

1200 |

2000 |

same as centrifuge |

400 |

600 |

|

|

* With and without coarse part

ejection.

** Throughput is dependant upon swarf form and material. |

|

|

|

|

|

|

|

|

T & A Trenntechnik & Anlagenbau

GmbH · Industriestraße 6 · D-77955 Ettenheim-Altdorf

phone +49 (0) 7822 / 446 760-0 · fax +49 (0) 7822 / 446 760-9 · E-Mail:

info@t-und-a.de |

|

contact contact |

|

print

print |

|

top top |

|

|

Swarf preparation

Swarf preparation